This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Fuels & Irradiated Materials Analysis

Technology Platform

About

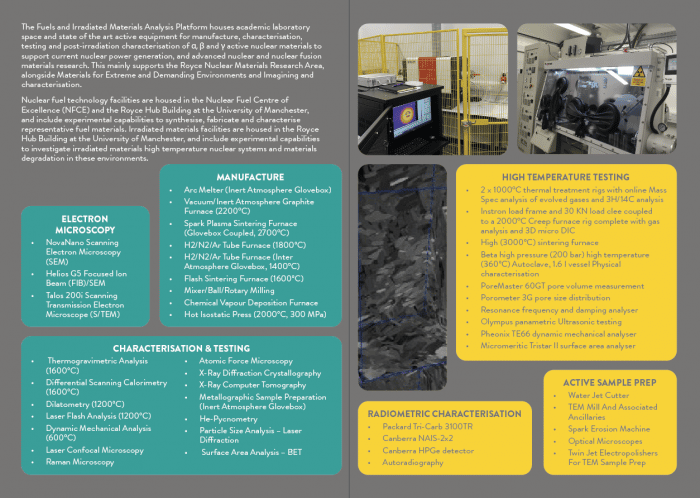

The Fuels and Irradiated Materials Analysis platform is a national, open-access facility for academic and industry collaborators via Royce or National Nuclear User Facility (NNUF) access schemes. It houses academic laboratory space and state-of-the-art active equipment for the manufacture, characterisation, testing and post-irradiation characterisation of α, β and γ active nuclear materials to support current nuclear power generation, and the advanced nuclear and nuclear fusion materials research areas. This mainly supports the Royce Research Area of Nuclear Materials but also supports Materials for Extreme and Demanding Environments (M4DE) and imagining and characterisation.

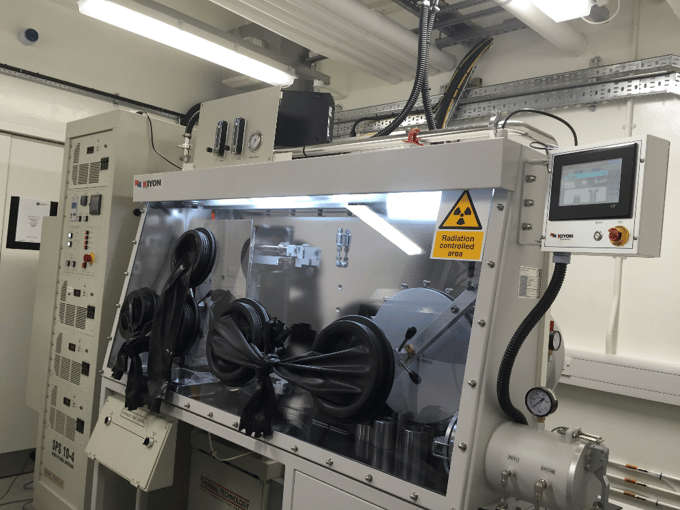

The nuclear fuel technology facilities housed within the Nuclear Fuel Centre of Excellence (NFCE) and the Henry Royce Institute at the University of Manchester include various experimental capabilities to synthesise, fabricate and characterise representative fuel materials. A suite of inert atmosphere gloveboxes, housing a variety of equipment, provide the capability to handle and process uranium- and thorium-bearing metals, ceramics and intermetallics. The research team at Royce? has developed capabilities to synthesise and fabricate representative fuel forms from a variety of uranic materials, including metal alloys, nitrides, silicides, carbides, borides and oxides. A range of experimental techniques have been developed over the past decade to allow thermophysical analysis, material characterisation and various forms of microscopy to be utilised on uranium-bearing materials.

Platform Lead

Rhys Thomas

Technology Platform Lead: Fuel and Irradiated Material Analysis

Rhys is a Senior Application Scientist in Nuclear Materials with over 10 years of experience in the field. He specializes in designing and executing complex experiments, including proton irradiation studies, micromechanics and synchrotron-based projects, delivering critical insights into material behaviour. His work bridges academic research and industrial applications, contributing to a deeper understanding of materials degradation. Passionate about collaboration and mentorship, Rhys has guided teams in advanced data analysis and developed open-source software for correlating strain maps with crystallography. In addition to contributing to 28 journal and conference publications, Rhys has successfully delivered projects in partnership with industrial collaborators, addressing real-world challenges.

Brochure

Watch

Technology Platform Lead Dr. Rob Harrison guides you through a best practice demonstration of SRIM for conducting a vacancy calculation. The Stopping Range of Ions in Matter (SRIM) Monte-Carlo simulation code is widely used to calculate radiation damage and quantify displacements in materials exposed to energetic ions and used in a range of applications. Although there are several methods in which to run SRIM for this, a series of guides and how-to methods of quantifying the radiation damage through the NRT displacement model have been published in recent years, this video demonstrates the method for calculating vacancy production proposed by Agarwal et al. in their 2021 paper published in Nuclear Instruments and Methods in Physics Research.

Equipment

Arc melter (inert atmosphere glovebox)

Vacuum/inert atmosphere graphite furnace (2200°C)

Spark plasma sintering furnace (Glovebox coupled, 2700°C)

H2 /N2 /Ar tube furnace (1800°C)

H2 /N2 /Ar tube furnace (inter atmosphere glovebox, 1400°C)

Flash sintering Furnace (1600°C)

Mixer/ball/rotary milling

Chemical vapour deposition furnace

Hot isostatic press (2000°C, 300 MPa)

Thermogravimetric analysis (1600°C) – including water vapour

Differential scanning calorimetry (1600°C) – including water vapour

Dilatometry (1200°C)

Laser Flash Analysis (1200°C)

Dynamic mechanical analysis (600°C)

Laser confocal microscopy

Raman microscopy

Atomic force microscopy

X-ray diffraction crystallography

X-ray computer tomography

Metallographic sample preparation (inert atmosphere glovebox)

He-pycnometry

Particle size analysis – laser diffraction

Surface area analysis – BET

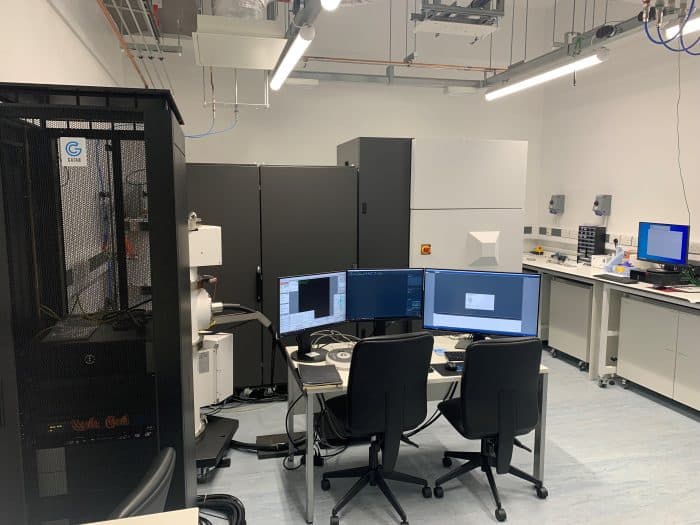

NovaNano scanning electron microscopy (SEM) equipped with:

- a Field Emission Gun (FEG) electron source

- electron Backscatter Diffraction Analysis (EBSD) and Energy Dispersive X-Ray (EDX)

- nano-indentation

- high temperature air/steam injection capability to examine high temperature corrosion and oxidation on the micron scale

Helios G5 focused ion beam (FIB)/SEM equipped with:

- a Field Emission Gun (FEG) electron source

- Secondary Electron (SE), Backscattered-Electron (BSE), Circular Backscatter Detector (CBS), scanning transmission electron microscope (STEM) detector – resolution of 0.7 nm

- Oxford instruments Ultimax EDS 170 mm2 detector, Oxford instruments Symmetry fast CMOS EBSD camera

- AutoTEM lamella preparation, Slice and view software for 3-D electron image, EDS or EBSD capture

- Alpha active loader with coupling to MBraun glovebox to permit fully contained workflow for alpha active nuclides

Talos 200i scanning transmission electron microscope (S/TEM) equipped with:

- FEG electron source with probe size down to 1 nm

- Bright-field (BF), Annular dark-field (ADF), High Angle Annular Dark Field (HAADF) detectors

- Dual Bruker EDS systems with energy resolution of 129 eV

- Gatan Continuum EELS camera for spectroscopy of EFTEM image acquisition, energy resolution of 0.9 eV

- Range of holders, including low background EDS, Cryogenic and Vacuum/ inert transfer holders to go from FIB glovebox to S/TEM without breaking of containment/exposure of the sample to air

The irradiated materials facilities housed within the Henry Royce Institute at the University of Manchester include various experimental capabilities to investigate irradiated materials high-temperature nuclear systems and materials degradation in these environments. The research team has developed a dedicated radioactive laboratory to prepare, characterise and test irradiated samples including graphite and Zr alloys. Equipment capabilities include sample machining, preparation, radiometric and radiological fingerprint characterisation (α, β and γ), microstructural characterisation (2 and 3D) including spectroscopic & crystallographic, and in-situ testing (both mechanical and environmental, and chemical and physical treatments with on-line spectroscopic evaluation). Further equipment specifications are given below.

A water jet cutter

TEM mill and associated ancillaries

Spark erosion machine

Optical microscopes

Supplementary facilities including ovens, balances

Twin jet electropolishers for TEM sample preparation

Various cutters, Diamond saws and active lathe

2 x 1000°C thermal treatment rigs with online Mass Spec analysis of evolved gases and 3H/14C analysis

Instron load frame and 30 KN load clee coupled to a 2000 °C Creep furnace rig complete with gas analysis and 3D micro DIC

High (3000 °C) sintering furnace

Beta high pressure (200 bar) high temperature (360 °C) Autoclave, 1.6 l vessel Physical characterisation

PoreMaster 60GT pore volume measurement

Porometer 3G pore size distribution

Resonance frequency and damping analyser

Olympus panametric Ultrasonic testing

Pheonix TE66 dynamic mechanical analyser

Micromeritic Tristar II surface area analyser

Packard Tri-Carb 3100TR

Canberra NAIS-2×2

Canberra HPGe detector

Autoradiography