This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Research Area

Advanced Metals Processing

Vision

The Advanced Metals Processing Research Area aims to build on the UK’s strength in metals processing and provide the support needed to deliver innovative metals processing technologies and novel alloy solutions.

It also aims to enable the UK metal industries to transition to a resource efficient, zero-pollution, digitalized and agile future.

Above: watch Professor Martin Jackson and Dr Ed Pickering introduce the Advanced Metals Processing Research Area.

The total worth to the European Economic Area of the manufacturing and processing of metals to form components

Introduction and Scope

Metallurgy and metals processing is changing, driven by the need to rapidly transition to a low-carbon and more circular economy. Improved innovation and in-service performance is required, whilst addressing the socio-economic drivers of reducing process waste, and emissions, and development cycle times.

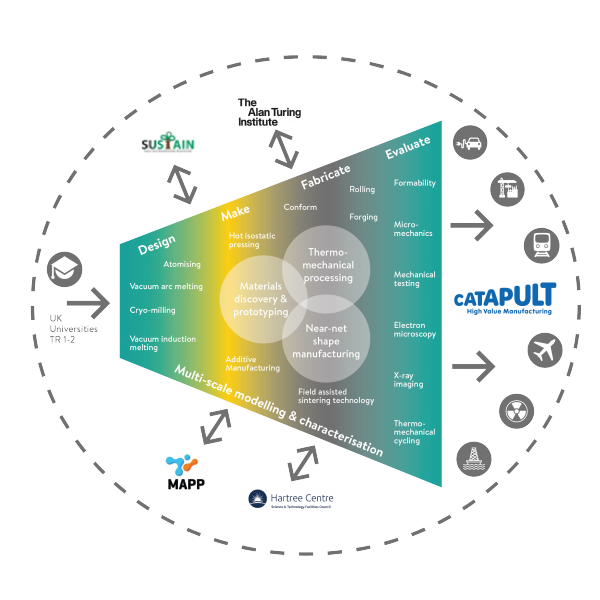

Our focus on metals process innovation is the “missing gap” between small-scale laboratory metals processing and the industrial scale. Through a combination of small-scale experiments, materials characterisation, and modelling, our aim is to develop an integrated computational materials engineering approach to metals processing across the whole manufacturing process, accelerating manufacturing agility and efficiency.

Led by the University of Sheffield, working with the University of Manchester, the Advanced Metals Processing Research Area engages the entire Advanced Metals community in the UK.

Application areas include:

- Light weight system solutions for transport industry;

- New steels for nuclear industry;

- Net shape aerospace components;

- Additive repair of high value components;

- Materials tailored for orthopaedic applications;

- Primary metal suppliers for automotive manufacturers;

- Primary metal suppliers for aerospace component manufacturers, gas turbine suppliers.

Current and Future Research

To facilitate and support the development of competitive, resource-efficient, zero-carbon, digitalised, and agile UK metals manufacturing, through:

- the adoption of new technologies based around heat from electricity/hydrogen

- Materials 4.0 (e.g. “digital twin”) development for rapid and intelligent

process support - new solutions for de-commissioning and recycling/re-use of metal products

(including understanding the resiliance of alloys to repetitive recycling) - the transition to more efficient and affordable processing routes with more

consistent properties to reduce design conservatism (use of less material

by challenging our approach to risk assurance).

Links

Our unique capability has been strategically designed to “stress-test” metals processing and alloy innovations (TRLs 1-2) at an intermediate size scale, and will then move to the industrial scale through the High Value Manufacturing Catapult (HVMC) network, Materials Processing Institute (MPI) and TWI.

Steering Group

| Name | Institute/Organisation |

| Abigail Ackerman | Imperial College London |

| Moataz Attallah | University of Birmingham |

| Kate Black | University of Liverpool |

| Dave Collins | University of Cambridge |

| Gebril El-Fallah | University of Leicester |

| Marina Galano | University of Oxford |

| Mikdam Jamal | Manufacturing Technology Centre |

| Mark Jones | CoNetZ |

| Nick Lavery | Swansea University |

| Jiawei Mi | University of Hull |

| Pete Osborne | University of Sheffield AMRC |

| Carl Slater | WMG |

| Tan Sui | University of Surrey |

| Matthew Bailey | Aerospace Technology Institute |

| Mark Dodds | ITP Aero UK |

| Joe Fixter | Boeing Research and Technology |

| Richard Jenkins | McLaren Racing Ltd |

| Melanie Lang | FormAlloy Technologies, Inc. |

| Jan Lukaszewski | Aluminium Federation |

| Ehsan Rahimi | Jaguar Land Rover |

| Robert Scudamore | TWI |

| Rebecca Shepherd | Thales UK |

| Tom Williamson | Atomising Systems Limited |

| Yogiraj Pardhi | Sulzer |