This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Developing A Novel Tomography System for Improved Materials Visualisation

Case Study

Overview

Next-generation materials require precise, multifaceted control of manufacturing conditions to realise their full technical and economic potential. The progression from lab-scale R&D to the factory floor is a critical challenge. Novel “Materials 4.0” technology uses electrical sensing principles to make it quicker and easier to take next-generation composite materials to market.

Adjacency Group, a business working with sustainable composite / nano-material technologies for consumer and automotive markets have developed a novel tomography system to integrate sensor data into a deeper and richer visualisation of material state with the support of funding from the Royce Industrial Collaboration Programme.

About the Project

Current sensing technologies used in the design and development of composite materials are typically “black boxes”, restricting the materials developers’ ability to understand underlying material state and dynamics. And, these systems are usually expensive and lack robustness, making them difficult to deploy in a manufacturing environment.

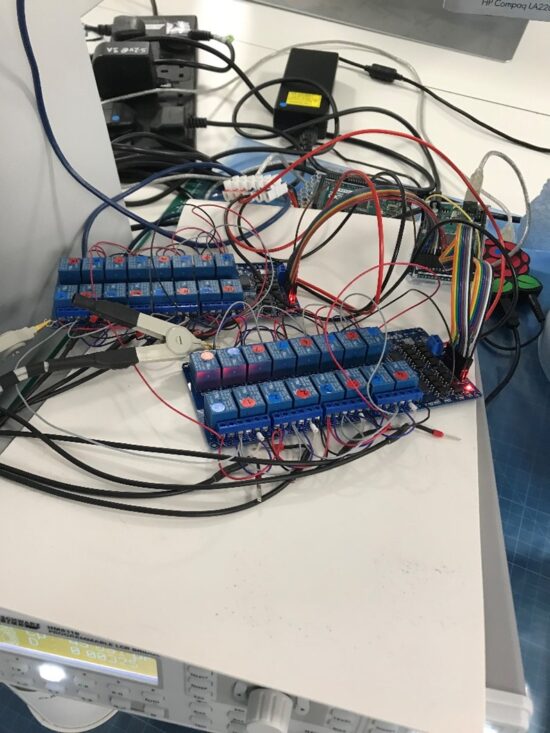

Innovation – to overcome these issues and meet the needs of new materials developers, the research team developed a novel electrical sensing system capable of detecting changes in material state in real-time, using relatively low cost but accurate electrical sensing principles, and providing full access to the underlying raw data.

Novelty – This is a totally novel application in composites manufacture, with the ability to visualise material state in real-time accelerating R&D (identification of key material and process parameters) and enhancing resultant part quality. Unlike the industry typical “black box”, by providing full access to the underlying data, the system will also enable enhanced AI / Machine Learning integration.

During this project, in collaboration with project partners at WMG and the University of Bath, Adjacency Group developed a novel low-cost, multi-channel electrical tomography system, including all required electrical hardware and tomography / visualisation software. This provides a step-change over existing electrical sensing systems typically used in composites R&D and manufacture, having both a broader range of sensing capabilities, and being able to integrate sensor data into a deeper and richer visualisation of material state. The solution uses a simple visual interface (spatial heat-map) and provides access to underlying data collected by the system, allowing calibration for a wide range of material characteristics – which should prove a critical benefit to material developers when designing new materials.

Future Impact

By making it quicker, easier, and cheaper to develop and scale manufacture of next generation composite materials, the unique technology should help sustain and build the UK’s high-value / strategically critical advanced materials industry – helping achieve the UK government’s vision for a sustainable, thriving, agile, and resilient manufacturing industry. The technology supports advanced material R&D and downstream manufacturing, including the Automotive industry, which is critical to the UK’s regional manufacturing economy. Economic growth from next-generation composites will support employment and exports across multiple industry verticals and value chains, from materials and manufacturing to marketing & distribution. Enabling next-generation sustainable composite materials, the technology can accelerate the shift to low- cost, high performance, sustainable composite materials, contributing to the Net Zero agenda. As a platform technology, the unique electrical tomography system, built using low-cost hardware and providing full data to underlying material state, can help new material developers in the UK refine and scale-up their advanced material technologies, and these benefits can spread beyond the materials industry, encompassing new applications technologies which can exploit quicker, lower cost materials R&D.

Composite materials are a strategically vital £70bn global industry, spanning a range of high-value applications, from aerospace to automotive. The next generation of composite materials will play a key role in the transition to net zero, coming into play everywhere from light-weight vehicle architectures to fully recyclable wind-turbine blades.

Adam Connolly

Managing Director, Adjacency Group Ltd

Collaborators

The work was completed with lead organisation Adjacency Group Limited, working with partners at Warwick Manufacturing Group and the University of Bath.

The work was enabled due to a grant from the Henry Royce Institute’s Industrial Collaboration Programme.