This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

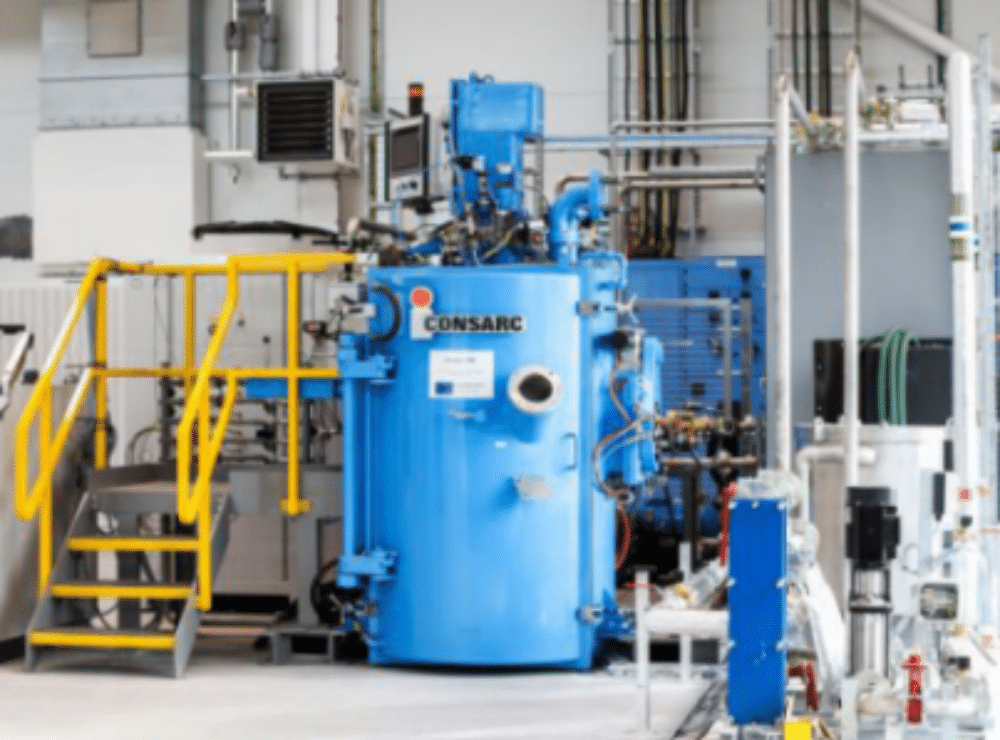

Vacuum Induction Melting (VIM) furnace with ISM coil for alloy manufacture

- Partner:The University of Sheffield

- Facility:Royce Translational Centre (RTC)

- Availability:Available

Or call us now on 0161 275 8382

Detailed Description

Unlike many VIM systems, this one is capable of melting reactive metals such as Ti and Zr up to 3 kg using ISM crucible. In regular VIM mode, it can melt up to 25 kg Fe, Co, Ni, Cu-based alloys. By controlling the chamber pressure and the temperature and with the help of inductive melt stirring, it is possible to obtain homogenous alloys with desired chemistry. Melting under vacuum conditions enables slag-free melting and riddance of unwanted dissolved gasses and elements. Maximum mould height can be 700 mm.

Uses/Applications

This equipment makes it possible to refine metals and alloys, and manufacture Ti alloys for aerospace and medical applications, Zr alloys for nuclear applications, V alloys for fusion applications, Co alloys for medical applications, special steels for nuclear applications, complex Ni-based alloys for jet engines and power plants. Alloys produced can be further processed via our Fenn hot rolling mill and Arcast ATM DM 50.

- Diffusion pump for rapid vacuuming up to 10-5 mbar

- Partial pressure operation in a pressure set between 20 mbar – 100 mbar,

- User-friendly PLC-based controls with touch panel, full data logging, and additions charging with manual over melt charger

- Power-driven crucible tilting.