This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Phoenix Materials Testing Limited, Bespoke

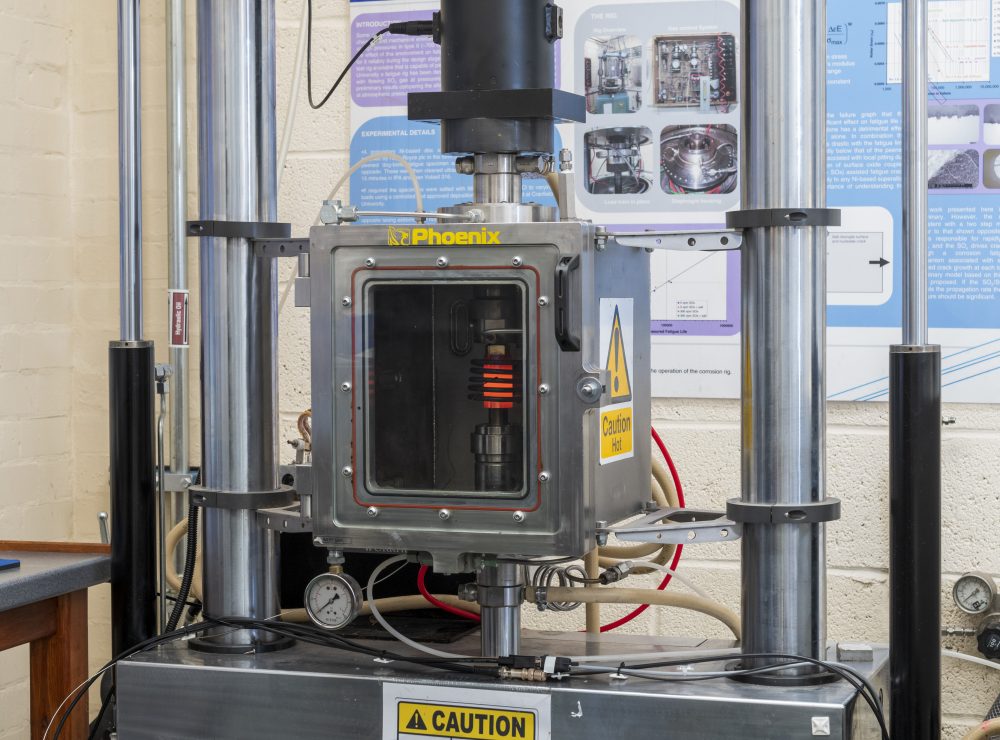

High Cycle Cryogenic Corrosion Fatigue Rig

60kN corrosion-fatigue rig with 100Hz capability. 77K to 1500K temperature capability

- Partner:Cranfield University

- Facility:National High Temperature Surface Engineering Centre

- Availability:Available from March 2024

Or call us now on 0161 275 8382

Detailed Description

60kN servo hydraulic high cycle fatigue rig capable of testing specimens in simulated ‘real’ environments. The specimen is enclosed in a protective chamber allowing for testing in various gas environments with and without a contaminant (salt) deposit. Used predominantly to simulate gas turbine environments. Fitted with induction heating to allow for rapid heating.

Uses/Applications

Used to assess materials performance in simulated environments. It can also provide data for lifing models.

60kN, load control, complex cycles, up to ~100Hz (depends on stroke length and servo fitted). Induction heated very high temperature, multiple gas testing (subject to COSHH and Risk assessment), salt deposits (subject to COSHH and Risk assessment), TMF capable. DCPD crack growth. 77K to 1500K. Slow strain rate testing