This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Sample preparation using gas impregnation

- Partner:UK Atomic Energy Authority

- Facility:Materials Research Facility (MRF)

Or call us now on 0161 275 8382

Detailed Description

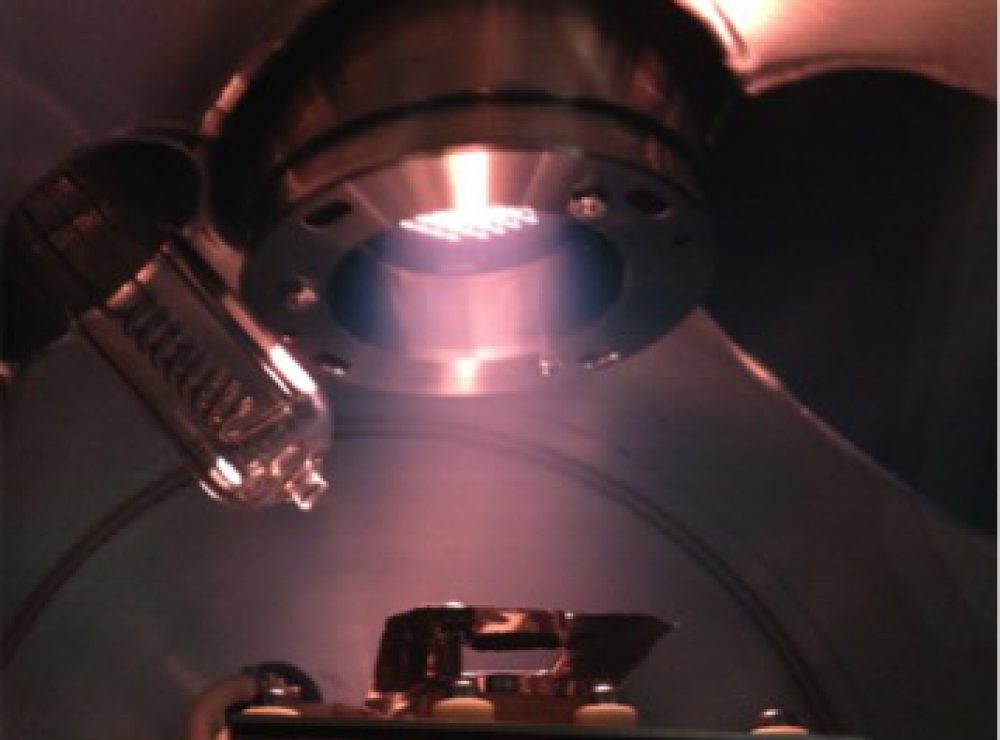

The Gas Impregnation Technique uses a vacuum system, with integrated sample stage and a plasma generator. The samples are loaded into the sample stage and evacuated to reduce contaminants. The plasma generator utilises a variety of gases, and produces a beam of accelerated ions with which to impregnate the sample.

Uses/Applications

The Gas Impregnation Technique is useful for samples that have a high impregnation energy barrier because the plasma energy can be many orders of magnitude greater to ensure gas impregnation to several microns deep.

Sample requirements

Sample size = 10mm x 10mm x 2mm

Surface roughness = 1-5 nm (mirror shine)

Gas impregnation

Gas = Argon, Nitrogen, Air, Helium, Deuterium & potentially more

Ion energy ≤ 500 eV

Sample temperature = Room Temp – 500 °C

Exposure Time ≤ 12 hours

Data Acquisition

Data captured = Plasma Spectrum, Light Power, Plasma Current, Sample temperature, Vacuum pressure

Sampling Rate = 0.5 Hz