This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

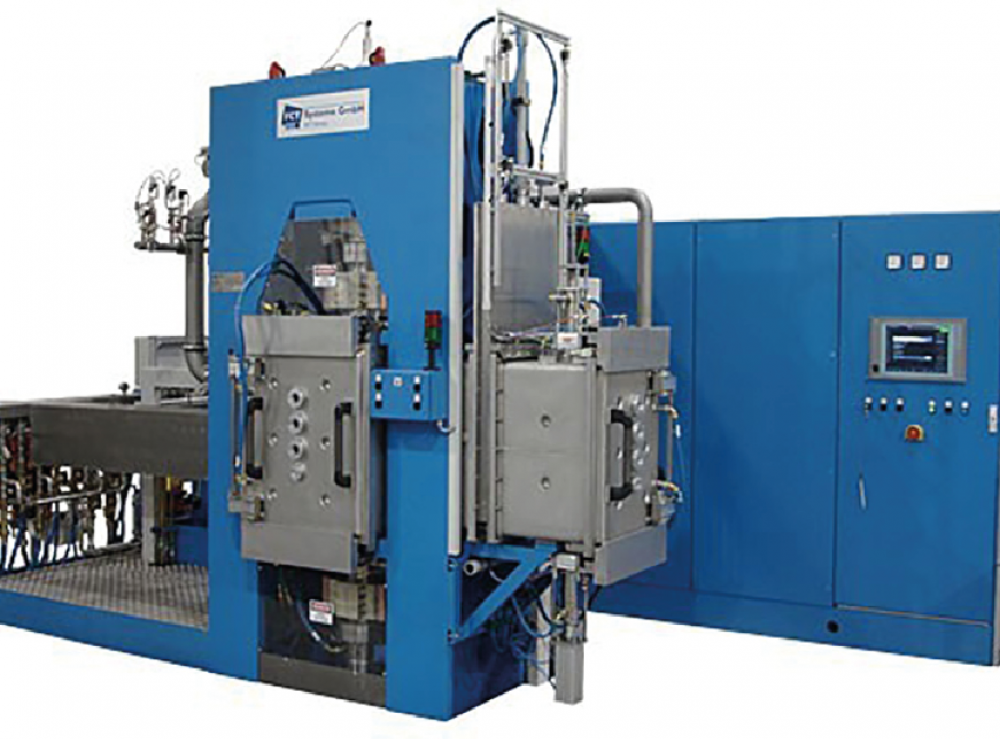

The HP D 250/C offers controlled and rapid solid-state sintering process enabling a range of particulate feedstock morphologies and chemistries to be fully consolidated into near-net-shape parts, or to create functionally-graded product forms for new applications.

- Partner:The University of Sheffield

- Facility:Royce Discovery Centre

- Availability:Available

Or call us now on 0161 275 8382

Detailed Description

The Type HP D250/C FAST/SPS furnace is ideal to investigate the scale-up of this technology to industrially relevant component dimensions across a variety of sectors. The secondary cooling chamber (unique within the UK) facilitates semi-continuous processing to demonstrate the potential economic benefits of increased throughput production.

Uses/Applications

FAST/SPS processing can consolidate a wide-range of metallic, ceramic, and functional materials. In general, the ability to utilise lower processing temperatures and/or shorter processing times allows the production of unique properties compared to conventional powder metallurgy sintering techniques, which make FAST/SPS attractive across a vast range of uses and applications.

Examples include:

- Sintered nanomaterial without significant grain growth

- Functionally graded materials

- Multi-material composite materials

- Innovative carbide metals

- Metal alloys (Ti, Ni, Al, Cu, Fe, W, V, etc)

- Intermetallic compounds

- Structural and functional ceramics

- Diffusion bonded materials

- Component size from 80 mm diameter to 300 mm diameter

- Additional cooling chamber for semi-continuous operation to investigate industrial applications

- Maximum working temperature of 2200°C, with temperature measurement and control via axial/radial pyrometers and/or flexible thermocouples

- Heating rates of up to 300 K/min (depending on tool size and material)

- Fully programmable and customisable sintering cycles

- Comprehensive software for data recording and evaluation of all sintering parameters

- Vacuum level of 0.05 mbar or furnace atmosphere of Ar / N2

- Servo-hydraulic force control up to 2500 kN, and measurement of displacement and densification rate

- Maximum applied voltage, current, and power of 8 V, 48 kA, and 360 kW