This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Fully automated software controlled instrument for the measurement of contact angles of solids

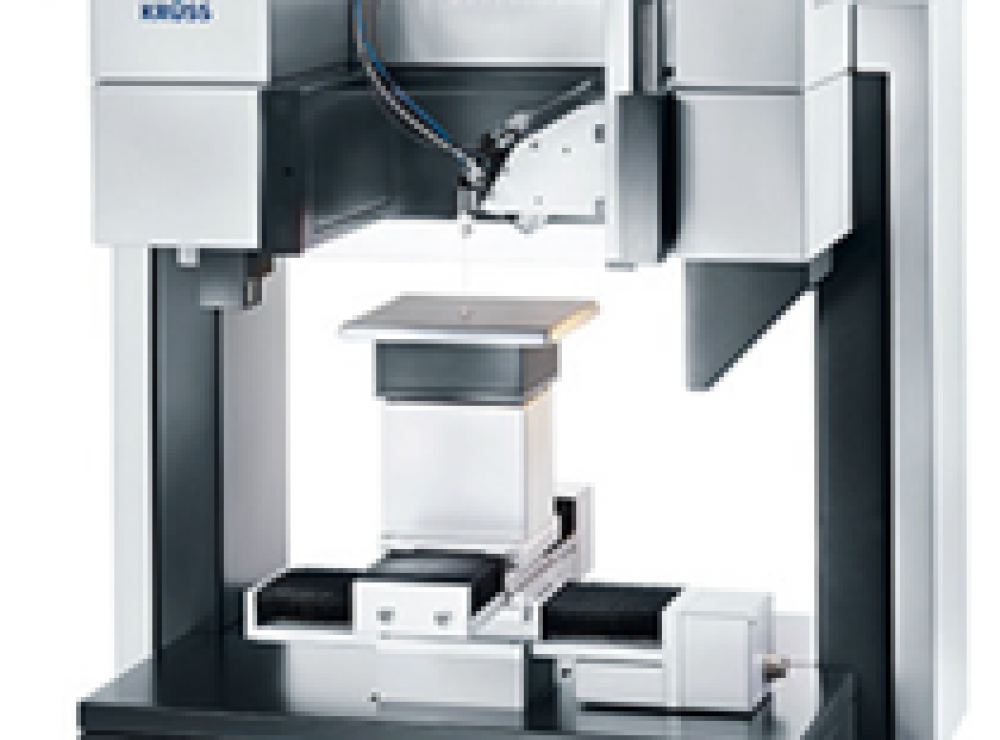

Kruss_DSA100E

- Partner:The University of Liverpool

- Facility:Materials Innovation Factory (MIF)

Or call us now on 0161 275 8382

Detailed Description

The Kruss DSA100E is a fully automated software controlled instrument for the measurement of contact angles of solids using the sessile drop method and surface tensions using the pendant method. The standard configuration can dispense 1-200μL volumes onto millimetre sized samples whereas conversion to the micro system allows smaller doses of 20pL to be dispensed onto samples in the micrometre range. The water contact angle provides valuable information on the hydrophobicity of the sample. Surface tension plays an important role in many different processes and is particularly useful for emulsion stability and determining the tendency for phases to separate.

Uses/Applications

The standard configuration is suitable for both sessile drop and pendant drop measurements for the majority of samples. Conversion from the standard into the micro configuration takes about one hour, however it allows far smaller dosing and the ability to measure the contact angle on smaller samples, for example hair fibres.

The micro configuration uses a Microdrop Technologies piezo system to dose 20 pL droplets and a more advanced x20 digital camera to capture the image before it evaporates (<1s).

Software controlled x,y,z stage

Software controlled dosing unit

Camera with 1200 x 800 pixels at 200 fps

Both surface contact angle and surface tension analysis

Conversion to the micro system enables 20pL dosing onto micrometre sized substrates