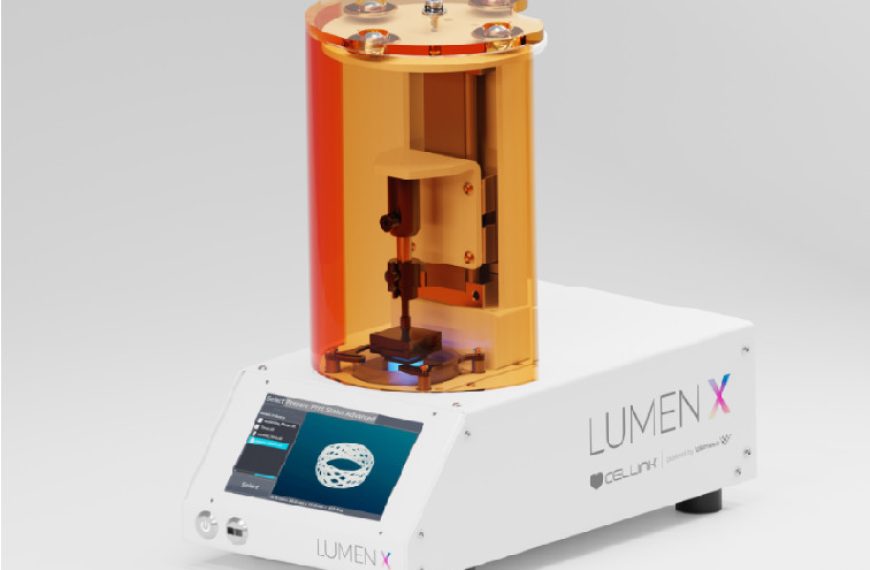

Description

Open biomaterial platform

Better cell safety with built-in UV sterilisation

Intelligent printheads for flexibility

Coaxial & mixing printing

Multi-material printing

Temperature-controlled printbed 4C-60C

Uses / Applications

Microfluidics

Complex microfluidic structures

With high precision and resolution, the LUMEN X Gen 3 enables the creation of complex microfluidic structures with intricate geometries for controlled fluid flow. Users can work directly with cells or seed them later. The LUMEN X eliminates lengthy casting processes and finally brings a much-desired, time and cost-effective solution for reproducible microfluidic fabrication.

Material development

Develop your own materials without workarounds

The LUMEN X allows users to develop and use their own materials without workarounds or extra fees, opening the door for the development of materials with unique properties and novel tissue engineering applications. With precision control over all key parameters like temperature, intensity and exposure times, researchers can glean a greater understanding of their material’s behavior.

Tissue Engineering

Addressing tissue-engineering challenges

Supported by the DLP technology, the LUMEN X enables researchers to address one of the most long-standing challenges – fabricating complex vascular networks. Coupled with grayscale printing onboard for the first time ever, the LUMEN X Gen 3 truly unlocks a new degree of capability in capturing in-vivo like conditions.

Drug Development

Providing greater insights & lowering costs

With LUMEN X Gen 3, we’re able to provide greater insight into the efficiency of medicinal candidates. With greyscale printing allowing multi-stiffness constructs, an increased build size, it is easier than ever to create diseased or healthy tissue constructs with fully accurate biomimetic properties. These constructs are ready to be dosed with compounds for evaluation in the early-stage compound selection process.