This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

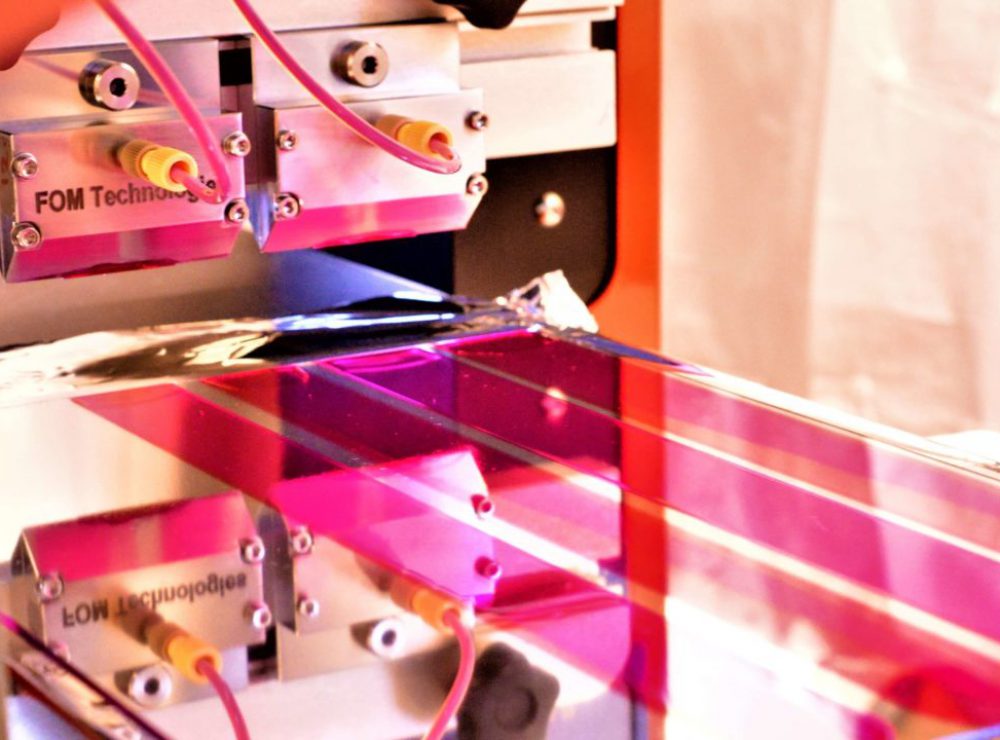

The R&D slot die coater is a highly compact, versatile, robust and easy to use system for the coating and drying of functional materials onto rigid and flexible substrates.

- Partner:The University of Sheffield

- Facility:Sir Robert Hadfield Building

- Availability:Available

Or call us now on 0161 275 8382

Detailed Description

The system is standard equipped with slot-die coating heads with additional coating and printing stations available on request. This powerful system enables its users to accelerate the development of new device structures, ink formulation and fabrication processes by reducing the gap between small batch processes familiar in R&D, such as spin coating, and continuous roll-to-roll processes necessary for large scale production.

Uses/Applications

The slot die coating system is designed for solution or slurry based deposition from 1-100 microns in the fields of low temperature co-fire ceramic modules, multilayer ceramic capacitors, multilayer actuators, fuel cells, solid state batteries, solar cells, thermoelectric generators, etc.

Features

State-of-the-art coating, very low dead-volume, elegant change of coating width, and versatile operating system.

The Slot Die coating head is available for 100mm coating width.