This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Materials and Coatings for Extreme Environments

Technology Platform

About

The Materials and Coatings for Extreme Environments Technology Platform is part of the long-established National High Temperature Surface Engineering Centre at Cranfield University. Our aim is to offer a complete package of expertise on coating systems from conceptual design and manufacture to performance evaluation in extreme environments. We are continuously seeking to evolve our capabilities through discussion with business, funding bodies and our Royce partners to continue to provide a world-leading bespoke facility. The work we do has a multitude of benefits, including reducing inspection times, increasing component life, selection of better materials/coatings, and informing designers for improved design. All of these contribute positively to reducing environmental damage through reduced wastage (increased component life), increasing engine efficiency (burning less fuel), and using more sustainable alloy and coating systems. Due to the diversity of the work, there are two Technology Platform Leads (TPLs) who specialise in two key areas: advanced coatings technologies and high temperature materials performance.

Platform Leads

Dr Christine Chalk

Technology Platform Lead: Coatings for Extreme Environments

Christine is a Senior Research Fellow in the Department of Manufacturing and Materials at Cranfield University. She graduated from the University of Sheffield with a BSc in Chemistry in 1976 and a PhD in Chemistry in 1980. She worked for 10 years at Fulmer Research Institute on various projects, including high temperature coatings for niobium alloy rocket thrusters. She then took some time out to raise her family and worked part-time in education. In 2006, she came to Cranfield, initially joining the National High Temperature Surface Engineering group as a technical member of staff, gaining wide experience of the field and then moving into research and academic positions. She mainly works on coating systems for protection in extreme environments using a range of deposition techniques, CVD, PVD and some electroplating but also on performance testing, including erosion and ballistic impact, high-temperature oxidation resistance, and chemical resilience of coating systems. She has worked with Rolls-Royce for many years developing higher performance thermal barrier coatings, and exploring newer ceramic materials, microstructural variations, and multi-layered systems for improved resilience. More recently, she has been involved in initial projects looking at potential hydrogen permeation barriers and the development of a high temperature (< 1600°C), high water vapour thermo-cyclic test rig in response to industrial demands.

Dr Simon Gray

Technology Platform Lead: Materials Performance in Extreme Environments

Simon Gray is a Principal Fellow in the Department of Manufacturing and Materials at Cranfield University. He graduated in Materials Engineering (MEng, 1996) from the University of Birmingham in the UK and subsequently obtained his PhD in 2000 from the same institution, looking at developing coatings for TiAl alloys. Until joining Cranfield in 2006, he remained at Birmingham, focusing on the performance of materials and coating systems, in particularly oxidation and creep. At Cranfield University, he initially focused on coating deposition including CVD and thermal spraying, and the oxidation and corrosion performance of these systems. During this time, he became more focused on the performance evaluation of materials at elevated temperature, and is now running a world-leading test laboratory looking at high-temperature accelerated oxidation, corrosion, stress-corrosion cracking, and corrosion-fatigue performance of materials systems in aggressive environments (including hydrogen). The equipment has been designed to facilitate ‘real-world’ needs, and provides critical performance data to enable significant improvements in “lifing” data.

Coatings for Extreme Environments

Our aim is to design and manufacture tailored coating systems (often multiple coating layers) for extreme environments which can include high temperature oxidation and corrosion, mechanical damage (erosion and wear), and specific chemical attack eg volcanic ash. More recently, there is a need for deposition of barrier layers eg to mitigate hydrogen permeation. This group considers surface preparation and interaction between – and evolution of – coating layers during service to be part of the design and manufacture service. We also offer a verification service using our high-end microscopy suite, XRD, and adhesion testing facilities.

Our thermal CVD facility offers non-line of sight deposition of Al, Cr, Si, Y and Hf using halide precursors at temperatures up to 1100°C, and inert gas atmospheric pressure with potential for co-deposition of elements eg Al and Cr or Al and Si, on a wide range of substrates. Processes include in-pack, above-pack and vapour phase providing opportunities to coat a wide range of substrates (allowing for material composition and morphology eg single crystal or polycrystalline). Development of modified processes can be supported by use of FACTSAGE thermodynamic software.

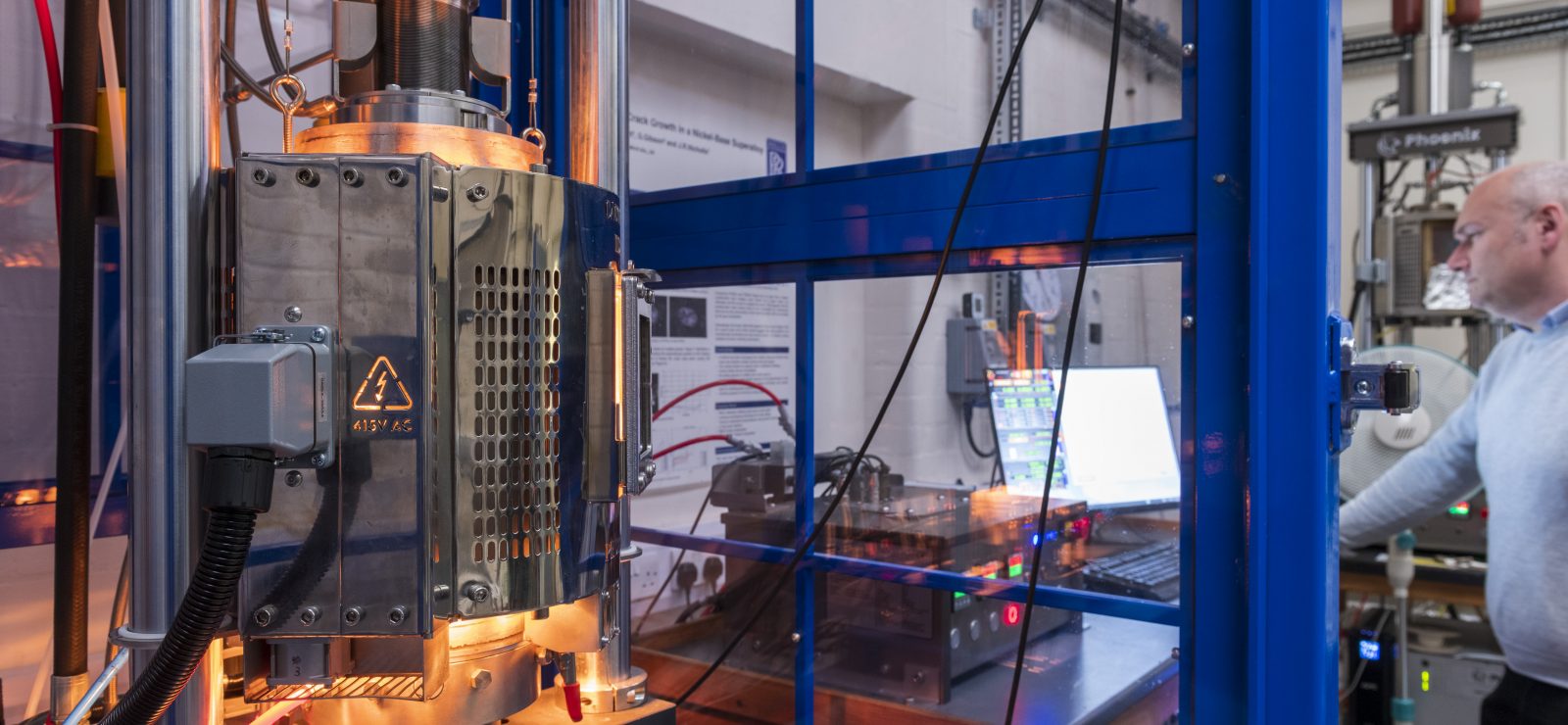

The Von Ardenne EB-150 features a jumping beam system and can evaporate up to three ingot sources sequentially in rapid succession, allowing for the production of multi-layered, graded or blended coatings. With up to 150kW maximum power demand and 40kV maximum acceleration voltage, this versatile large rig is capable of coating multiple substrates, including high-pressure, high-temperature turbine blades for aeroengines with ceramic coatings at temperatures of up to 1000°C in a controlled oxygen/argon environment. It is mainly used for deposition of zirconia-based thermal barrier coatings, although deposition of other oxide systems can be achievable subject to suitable evaporation characteristics.

Also available is a smaller, single-source EB-PVD rig with 14kW maximum demand power supply. Two substrate holders can accommodate multiple substrates, or two gas turbine blades and deposition can take place at temperatures up to 1030°C in a controlled oxygen atmosphere.

Our PVD facilities include a 4 x planar magnetron sputter coater (target size 345mm x 145mm), sputtering horizontally. Substrates are mounted on an 8-station carousel or can be mounted on a flat holder (150mm x 150mm) and rotated in front of the flux. The system is fully automated, allowing deposition of more complex recipes using pulsed-DC power supplies. Substrate bias and glow discharge cleaning are also installed.

Also available is a dual source barrel sputterer with 2 x planar magnetrons for coating complex components and powders by tumbling them in a barrel under the flux. The system is fully automated to allow complex recipes to be deposited, and the facility is extracted to handle more hazardous powders.

Our final PVD rig is a multi-source coater capable of mixing coatings by sputter deposition, thermal evaporation or electron beam evaporation. It can be used to deposit polymeric coatings by plasma-activated deposition processes or metal-polymer multi-layers.

We offer a range of plating techniques including electroplating of nickel, cobalt, and some precious metals, and electroless nickel plating for non-conducting samples. Brush electroplating is a very versatile technique allowing for in-situ plating of components, and for inclusion of particles in the plating solution to deposit metal matrix composites. The properties of the electroplated layer can thus be modified (eg to increase wear resistance).

Materials Performance in Extreme Environments

Our aim is to develop and execute unique test capabilities to simulate ‘real-life’ scenarios. Standard testing is not sufficient to understand how materials operate in real situations. Lack of relevant testing can lead to poor selection of materials systems in engineering environments. This can result in catastrophic failure, increased maintenance, higher material wastage and poor reliability, to name but a few. It was with this in mind that this test facility was established some 35 years ago and has been evolving ever since to meet continuously changing needs, particularly in demanding environments such as hot-corrosion, extreme thermal cycling, hydrogen, corrosion-fatigue, and erosion. Not only do we test but we also offer a wide array of support to interpret what our testing produces such as fundamental mechanisms with the assistance of our high-end microscopy suite and generation of “lifing” models to predict damage or component life.

The hot corrosion cells are designed to run in a multitude of different gaseous environments to simulate corrosion in the wide spectrum of real-life environments, such as gas turbines and boiler tubes (fireside corrosion). Along with this, ‘in-house’ image analysis is used to map the metal loss of the test samples to provide accurate corrosion damage estimates? and produce statistical damage models.

Designed to run in a multitude of different gaseous environments in order to simulate corrosion in the wide spectrum of real-life environments with particular emphasis on gas turbines. The added benefit of this rig is that it has two furnaces that can be set to different temperatures so that the specimens can be cycled between them, and at room temperature if required, whilst being fully enclosed in the test environment. Along with this, ‘in-house’ image analysis is used to map the metal loss of the test samples to provide accurate corrosion damage estimates.

100kN servo hydraulic fatigue rig capable of testing specimens in simulated ‘real’ environments. The specimen is enclosed in a protective chamber allowing for testing in various gas environments with and without a contaminant (salt) deposit. Used predominantly to simulate gas turbine environments. Recently retrofitted to allow PD fracture area measurement.

20kN servo screw fatigue rig capable of testing specimens in simulated ‘real’ environments. The specimen is enclosed in a protective chamber allowing for testing in various gas environments with and without a contaminant (salt) deposit. Used predominantly to simulate gas turbine environments. The environment can be pressurised up to 32bar in order to establish pressure effects.

60kN servo hydraulic high-cycle fatigue rig capable of testing specimens in simulated ‘real’ environments. The specimen is enclosed in a protective chamber allowing for testing in various gas environments with and without a contaminant (salt) deposit. Used predominantly to simulate gas turbine environments. Fitted with induction heating to allow for rapid heating.

50kN servo hydraulic fatigue rig capable of testing specimens in simulated ‘real’ environments including pure hydrogen at temperature. The specimen is enclosed in a protective chamber allowing for testing in various gas environments with and without a contaminant (salt) deposit. Used predominantly to simulate gas turbine environments. Fitted with light emitters to allow for rapid heating. PD capable to monitor crack area. 3- and 4-point bending jig attachment available with PD.

Two thermal cyclic rigs with lined furnaces, allowing for contaminant deposit to be deposited onto the specimen surface, breaking down the protective oxide without affecting the chemistry of the specimen due to rapid volatilisation of the deposit. Cheap to run and with the ability to separate out materials performance that a burner rig may not. Damage assessed by mass change whilst under test but by section loss metrology post-test if required.

Two thermal cyclic rigs with optional forced air cooling to enable controlled accelerated cooling rates. Damage assessed by mass change via periodic removal and weighing. Provides an accelerated and thus cheaper damage assessment compared to isothermal oxidation tests.

Two thermal cyclic rigs with aspirated water cooling to enable controlled ultra-accelerated cooling rates comparable to what may be seen in a gas turbine when ingesting water. Damage assessed by mass change via periodic removal and weighing. This test is extremely aggressive.

The high-velocity erosion rig from Cranfield University is a bespoke piece of equipment that can evaluate the performance of ceramics, metals, composites, and other materials and coatings against particle erosion. The operation of the rig is similar to ASTM G76, however, it is designed to accelerate larger particles at higher velocities at room or high temperature to replicate the environment of a turbine engine. Particles of up to 1mm in diameter can be accelerated up to 300m/s depending on their size (~100-200m/s for 100µm diameter particles) and the gas stream can reach up to 900°C, generating an eroded area of ~20mm in diameter.